We're specializing in short and big sized production series

Advantages of cooperating with us

Self sustaining tool making

Our tool park lets us produce our own press tooling while maintaining full control of the process

Assembly

Welding, spot welding, metal spinning, glueing or mechanical assembly - our experience lets us produce even most complicated, multi parts details for you

Powder coating

When requested we can powder coat any detail in any RAL pallet colour. This type of coating gives one of the best possible rust and abrasive resistances the detail can have.

About us

We’re producing car body parts since 1989. In the mid 90’s we were part of making a polish “Gepard” car project – most of the tools needed to produce it’s aluminum body was made in our company. While the car did not advance further that the prototype phase, we have gained a lot of experience with producing aluminum parts.

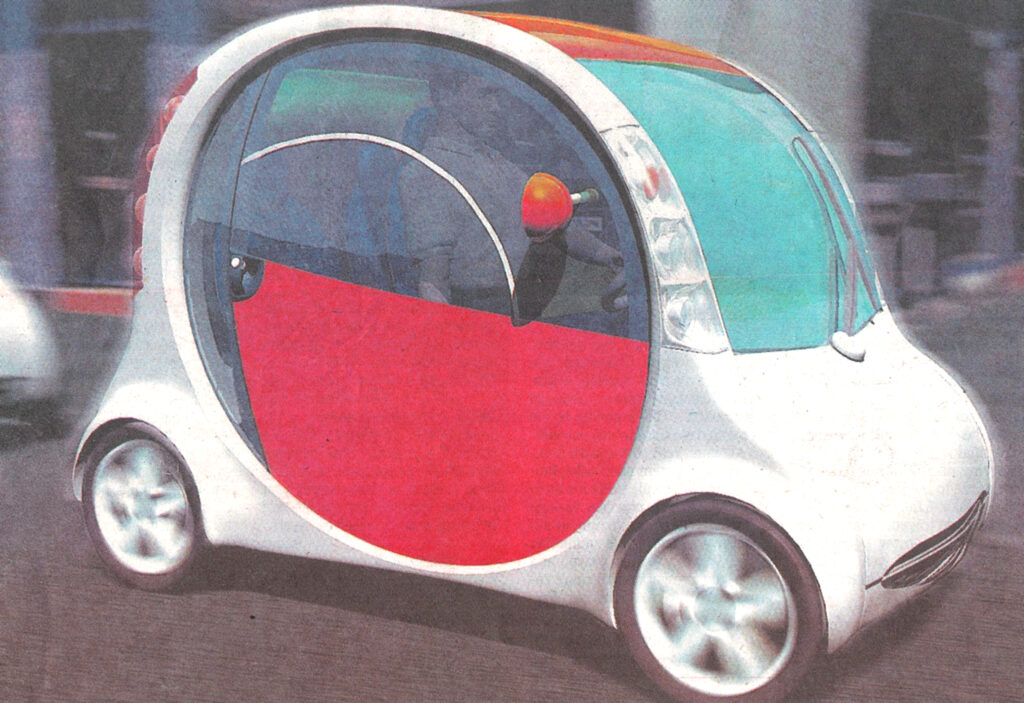

Between 2002 and 2004 we also helped with some elements of another prototype of a car under the name “Clic-car”.

With more than 1000 (dated 2023) references produced we can say with confidence that we are experienced with pressing all kinds of metal sheets ranging from carbon steel, galvanized steel, aluminum, stainless steel, perforated sheets and even metal meshes – whatever clients require.

In 2019 we have moved our company to Lubice where we now have already built 3300 square meters (as in 2023) and plan to expand even more.

The vast range of the details we produce covers all shapes and sizes – from small and simple repair panels and reinforcements through all kinds of sills, floors, wings and bonnets. Some of those details are also complicated, multi-part assembled details. We are confident in being able to make anything you need as long as it can be made from sheet metal of any kind.

While most of our current production is made from zinc coated steel and aluminum our range also covers details made from more exotic materials such as stainless steel, perforated steel and steel meshes.

Most of our production can fit two main segments, namely Classic car market and Automotive aftermarket. Usual orders for Classic cars are counted in tens or at most hundreds due to not many cars still driving today while Automotive ones usually count in hundreds or thousands.

Operating on those two vastly different markets is what makes us more flexible than others – we can adapt the technology applied to required production size.

Short series

When all you need is between 50 and few hundreds of the detail per year.

For such small series, exotic materials or even prototype work we can work with composite or hybrid steel-composite tools.

With this approach we are able to meet the Classic car or other small niche demands – offering top quality while keeping the tool costs few times lower than the traditional steel tool. Please keep in mind that the thickness of the detail does not go over 1,00mm.

On such tooling we can make up to few hundreds or thousands total detail count before the need of refurbishing the tool. This depends on material and shape of the detail.

This technology allowed us to become one of the world leaders in the market of Classic Car body parts. The lower entry cost does not compromise the quality – and our details for most demanding brands such as Mercedes, Porsche and Jaguar prove that point without a doubt!

Medium and big series

When you need hundreds or thousands pieces.

For such production we are using hybrid steel-composite or pure steel tools. We are able to make anything in thickness below 1,0mm. Products made from thicker steel may be possible as well, but has to be verified individually.

We have in offer some details made from 1,2mm; 1,5mm and even 2,00mm – all depends on the shape and material type of the detail.

We have developed proprietary tool making technology which enables us to make all kinds of tooling.

For projects with small lifetime volume of sales inexpensive composite tools which can produce few hundreds to few thousand pieces before needing refurbishment.

For high volume production we have hybrid steel-composite tools and pure steel tools. This kind of tooling can withstand tens of thousands of items produced without any issues.

Depending on the shape, thickness, material type of a desired product and the expected volume of the sales the design of the tool and applied type of technology will vary. We will keep close contact during designing process to fit the specific needs of any detail.

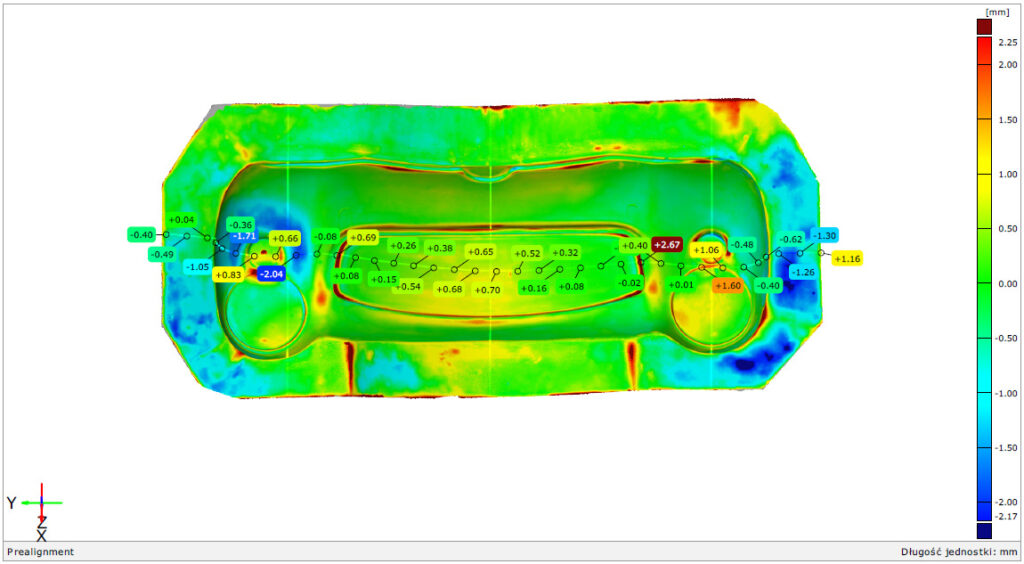

Making a new detail, e.g. a vehicle body element, requires first providing us with a physical sample, technical drawing or a digital scan of the detail.

While the composite press tools are up to a few times cheaper than steel tools they can still be a considerable cost for many projects.

We are working only on industrial presses using full set of press tools which makes us unable to make single piece of item on individual order.

We are not technically able to replicate single detail pieces.

Contact us

Visit us, call us or use the form on the right.

Visit us

Zakładowa 5, 05-340 Kołbiel, mazovian, Poland

Call us

SALIX Office tel:(+48)22 789 71 96

tel#2:(+48)25 307 03 15

Mon – Fri, 8:00-16:00

Deutsch

Deutsch English

English Polish

Polish